Celling 03. Flattening and offset#

Subject#

Importing initial shape (railing lines) for celling, checking of consistency

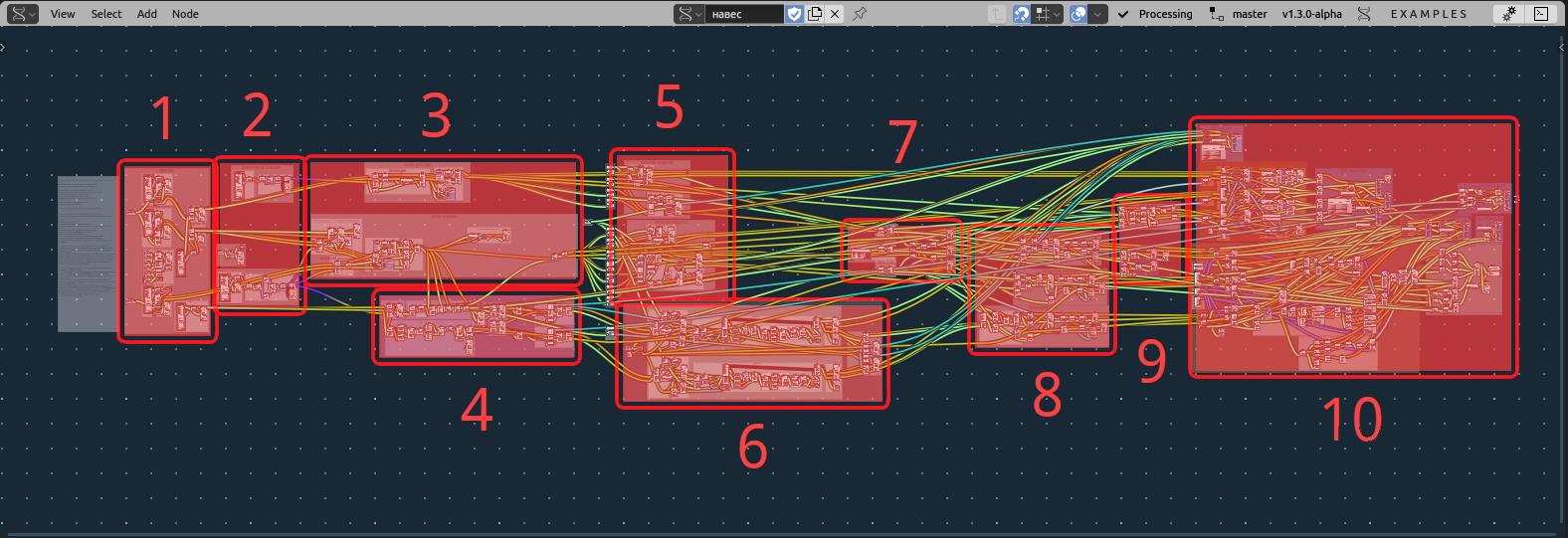

Node Tree#

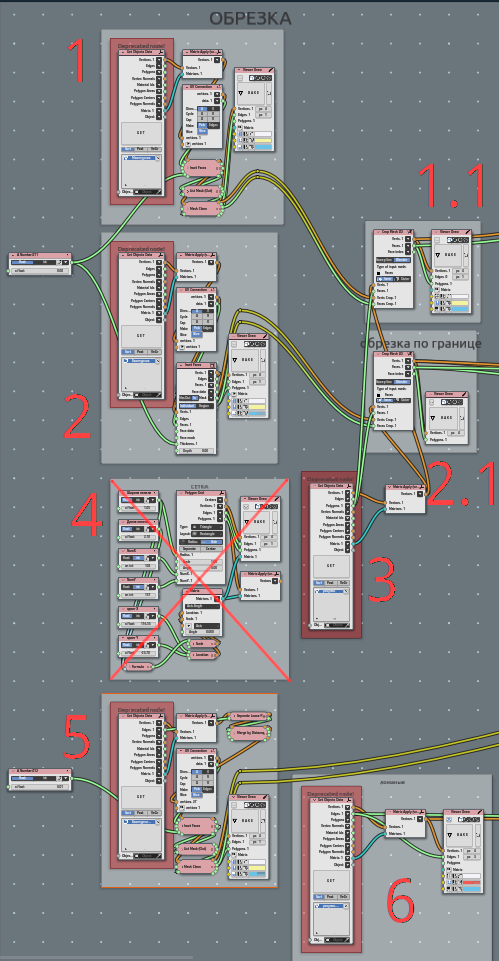

Import geometry:

- ObjectGet from scene - Small area’ boundary with incet faces at 0.003 m value;

1.1. Crop mesh (3) with that boundary;

- ObjectGet from scene - Large area’ boundary with incet faces at 0.003 m value;

2.1. Crop mesh (3) with that boundary;

Getting Rhomb Pattern manually created;

Attempt to create pattern parametrically, it fails only because simplicity of initial pattern to be manual;

Separately boundary for between-columns spaces;

Lines to manually determinecorner bended plates. It is diagonal for rhomb;

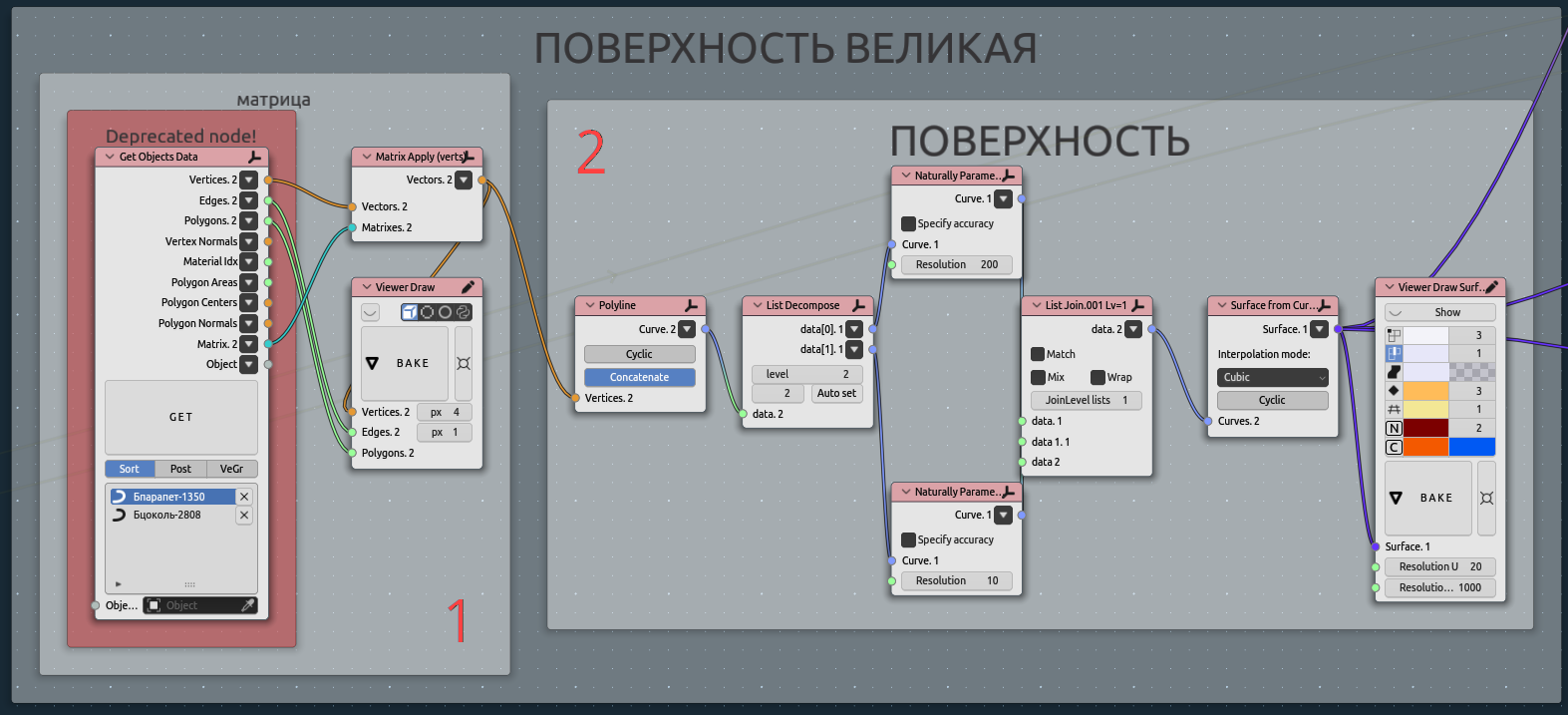

Making surface:

ObjectGet from scene - lower and ipper line for surface construction$

Making surface. In some cases needed natural paramereisation.

That step convenient to be in math surface, but far there we will go mostly mesh.

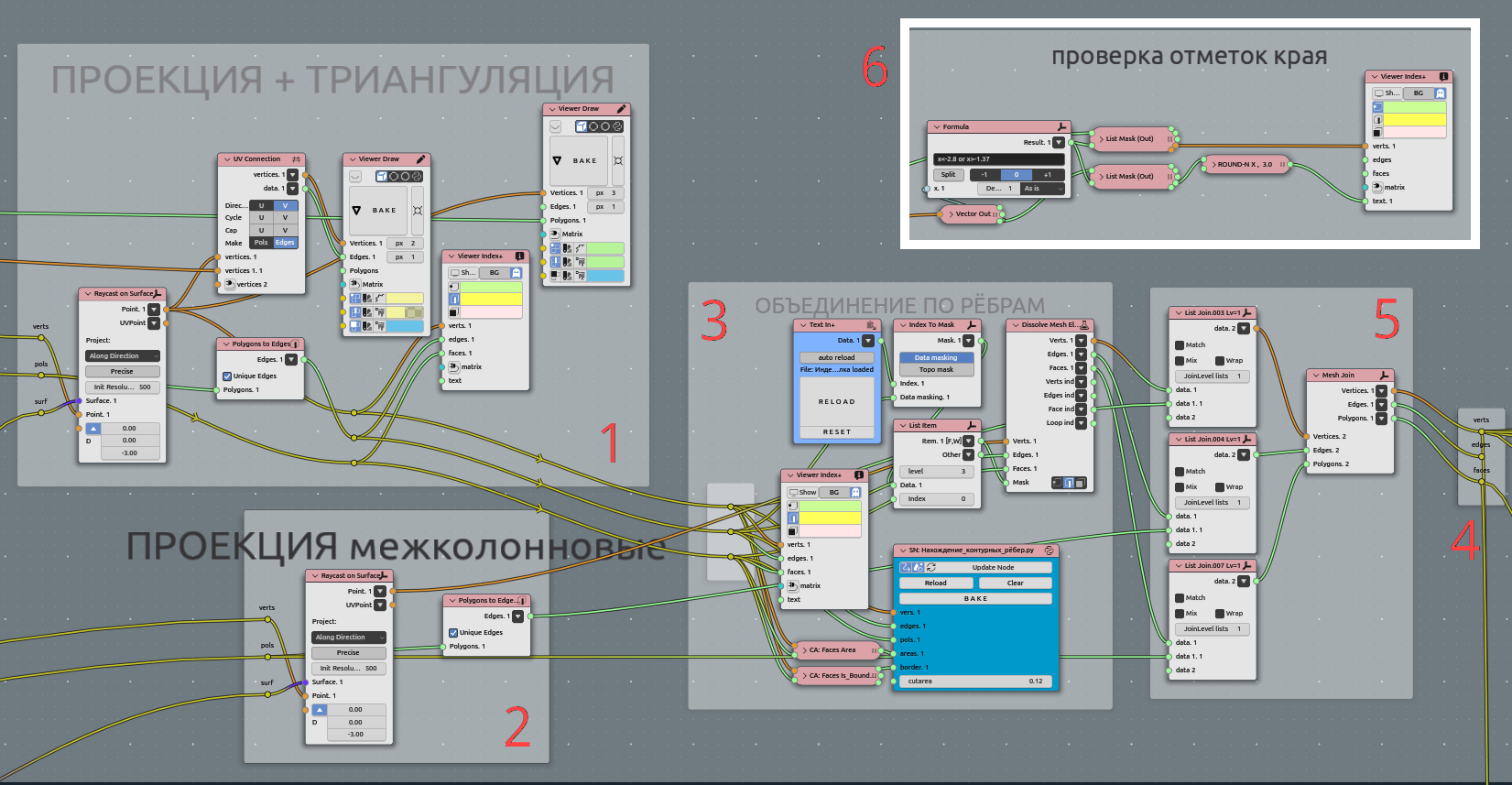

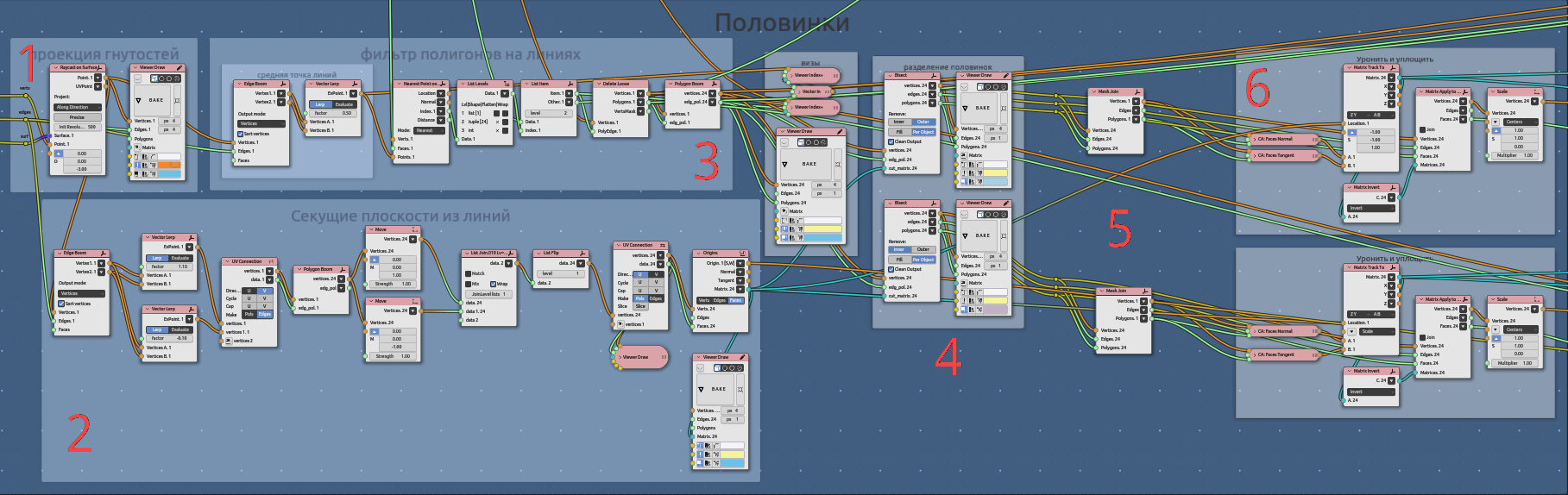

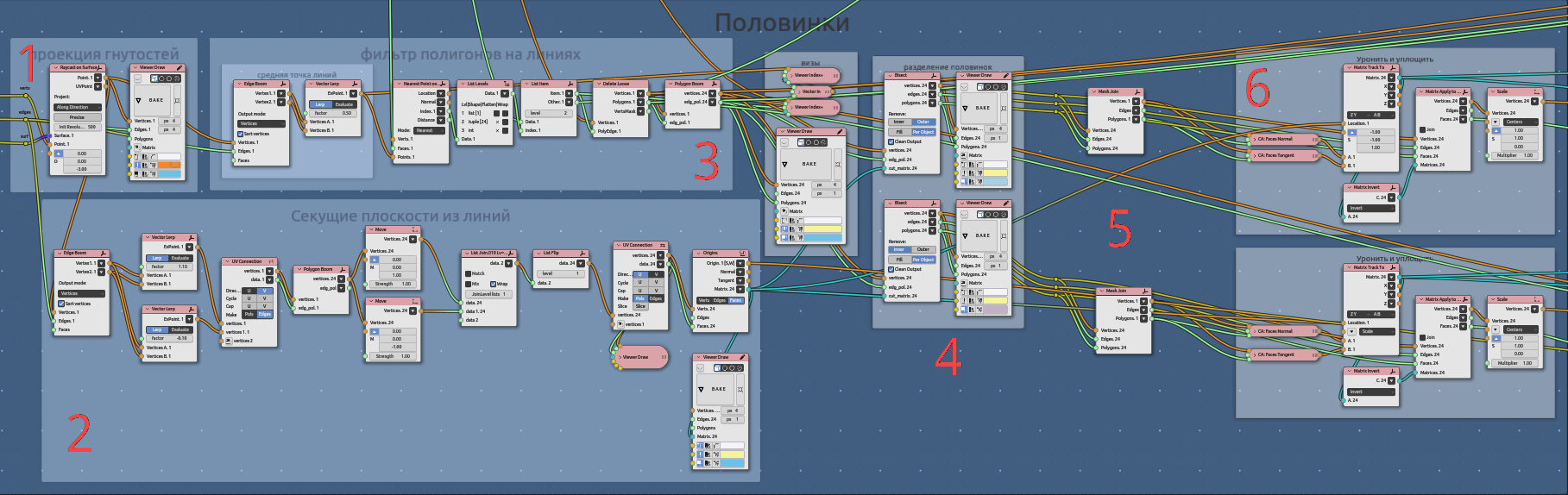

Projecting pattern to surface:

Raycast on surface main area;

Raycast on surface space between columns;

Most intriguing part - MANUAL angustment. Look for third part point 4. Dissolve;

Joining all geometry to one;

Convenient to make such reroute points (NodesMenu->layout->Reroute);

Additionallychecking all vertical dimentions to match initial line. We are using manually created lines in scene to adjust that Z-values. Maybe in some cases this checkout should be after flattening stage.

Separating bended corner plates:

Raycast pattern on surface corner area (edges);

Section matrices to separate left and right plate sides;

Select corner faces (not edges);

Bisect and separate left and right sides;

Join mesh;

Drop and flatten left and right sides separately;

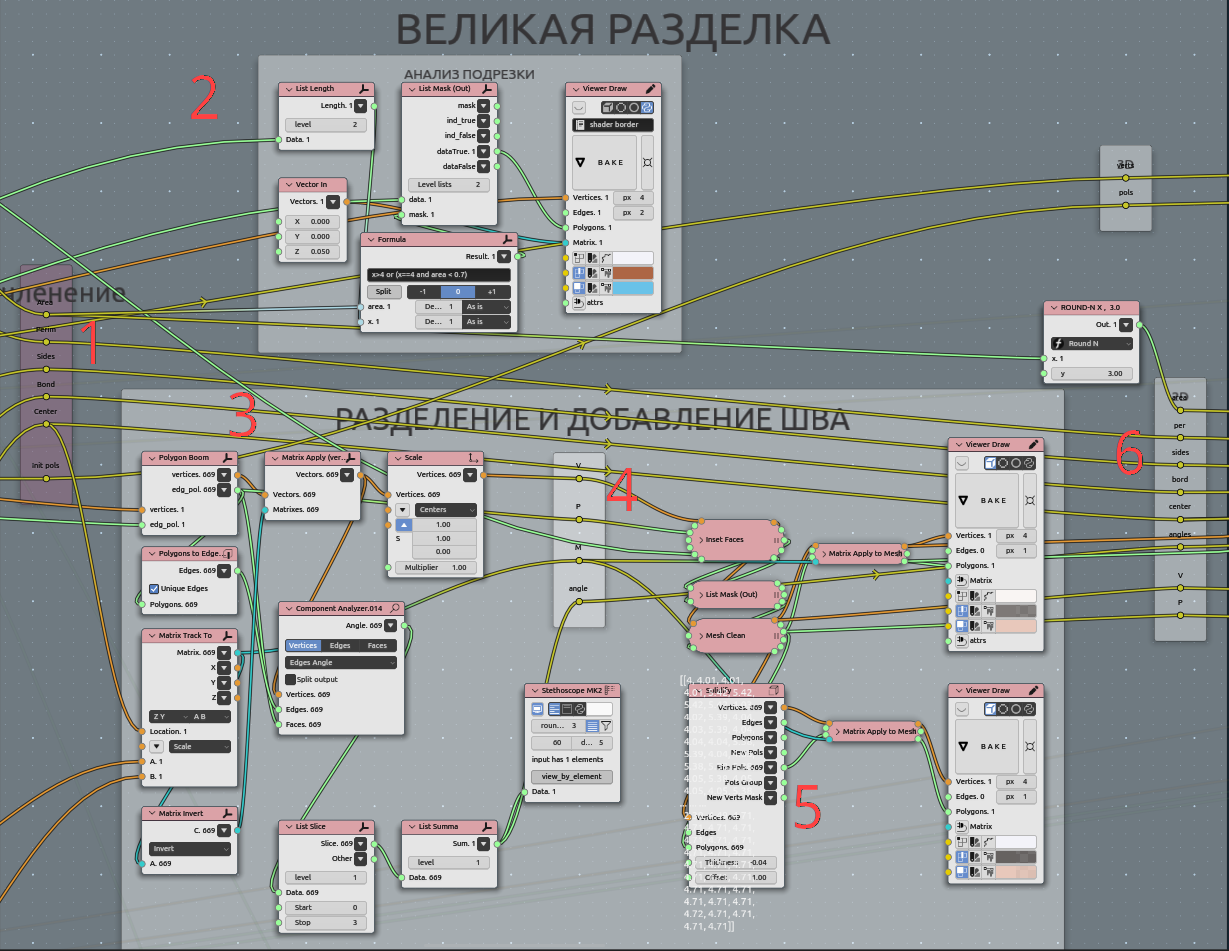

Flattening every plate:

Analytic outputs. There is row of analysis component node. There are area, perimeters, Nsides, IsBondary, Centers, Angles. All that going to 7 step, tipisation;

Visual checking for cutting parts. There is color highlighting for ngons;

Explode (boom node) polygons, dropping them on floor with inverted coplanar matrix for each plane, scale Z to zero (flattening itself);

Insetting gap between plates. So it appears line, compensating diferent deviations concerning flattening;

Also adding borders with extrude outer edges;

collecting rerotes for data on that step.

Sew corner splitted plates:

Demonstrating from one side:

Every plate merged by distance to be sure it consistent and sorted to manipulate after bisect disorder;

Mask formula. For every edge find out thouse of edges, are vertically oriented. That edges are bend edges, that needed to be joined when sewing left and right;

Loop for every plate. Input to that loop original “triangle” and inseted (gap between plates);

Tipisation of plates:

Drop plates to layout:

Testing and gathering:

Output: